Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod Lorem ipsum dolor sit amet consectetur adipiscing elit, sed do eiusmod lorem ipsum

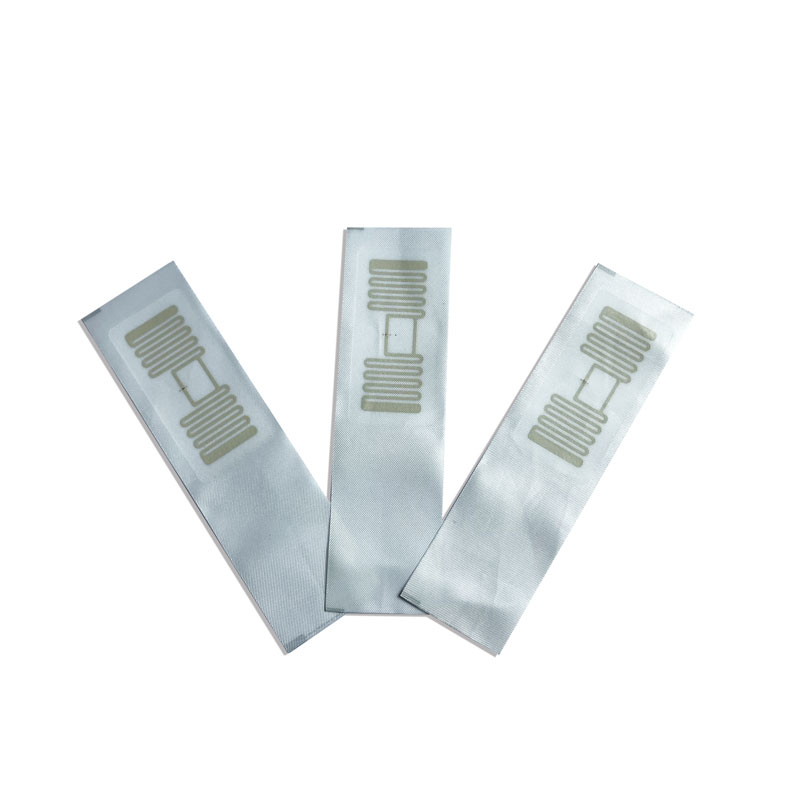

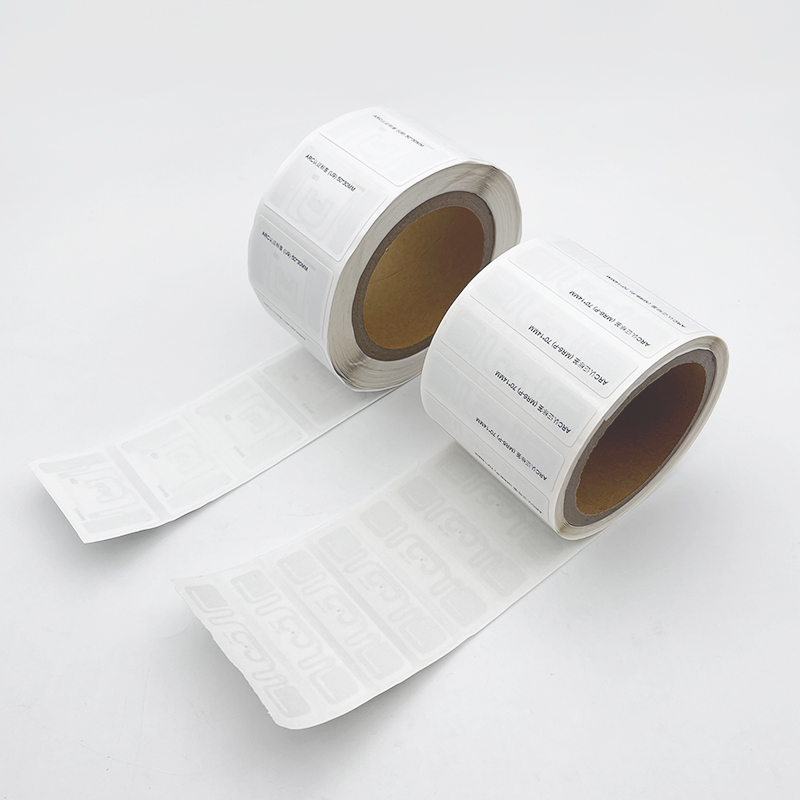

Anti-theft Long Range Tamper Proof UHF RFID Tags

Tamper-proof UHF RFID Tag with long-range tracking, secure asset management, and strong adhesive for logistics, retail, and anti-theft applications.

LPP Achieves 99% Inventory Accuracy with CXJsmart’s RFID Solution

LPP and CXJsmart achieved 99% inventory accuracy with RFID, reducing out-of-stock rates and speeding up checkout, setting a new standard in fast fashion.

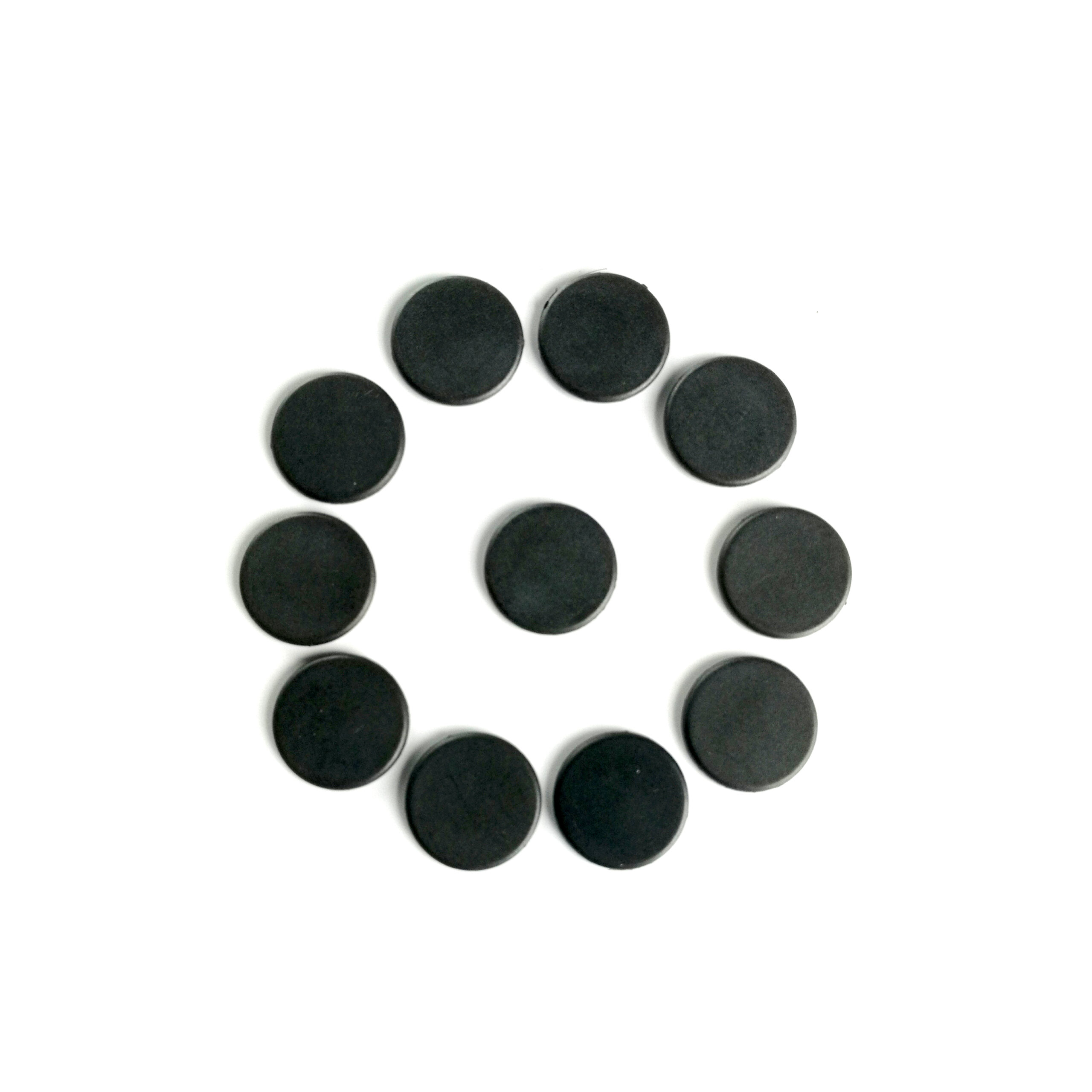

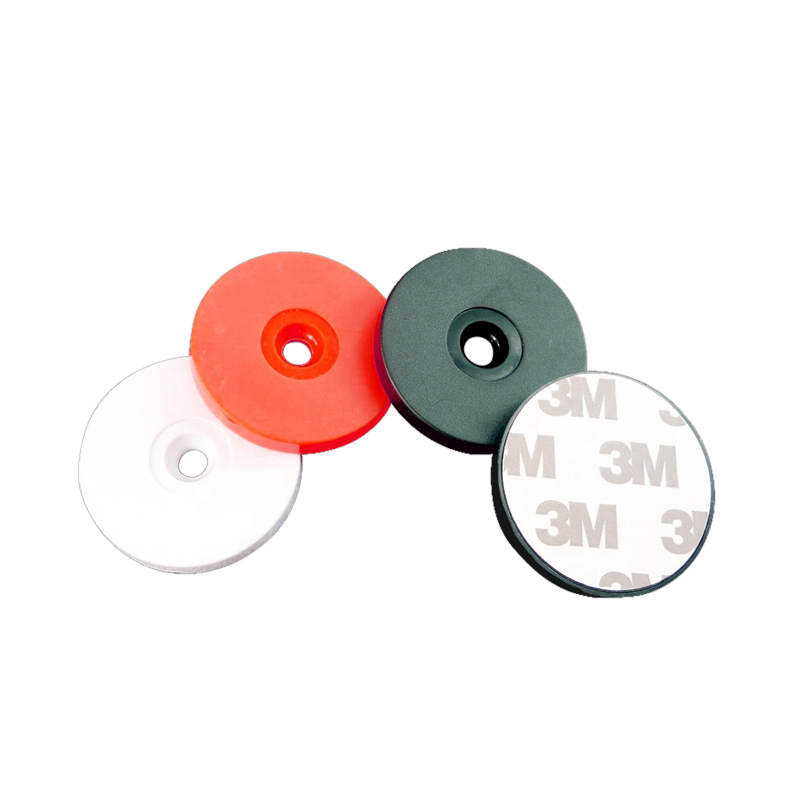

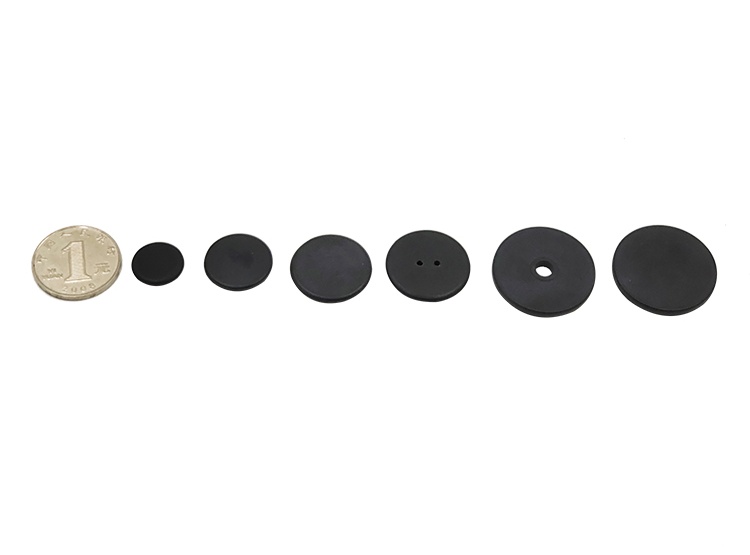

UHF 860-960MHz RFID Tags for Asset Tracking

Long-range UHF 860-960MHz RFID tags with waterproof design, ideal for asset tracking. Customizable sizes, high durability, and ISO/IEC 18000-6C compliant.