How difficult is it to “label” liquid products with RFID? Goodwin has a solution!

Many people may not know that some liquid products we usually see in supermarkets, such as car cleaning liquid, laundry detergent, and disinfectant, are actually much more difficult to manage than clothes and shoes. Why? Because the liquid in these bottles will “interfere” with the wireless signal, making the RFID reader “unable to see” the label clearly.

However, Goodwin Inc. and Phoenix Label are changing all this. They have jointly developed an RFID tag designed specifically for liquid products, so that these “unclear” products can also be tracked and managed smoothly.

RFID and liquids: brothers in distress?

RFID is a technology that can read information without contact and is often used in clothing, books, and warehouse management. It works by transmitting data through radio waves. But liquids and metals absorb or reflect these waves, so RFID signals often “fail” on liquid products.

This is a big problem for manufacturers who produce and sell cleaning products and automotive chemicals. Especially for large retailers like Walmart, suppliers are required to use RFID technology for product tracking. If they cannot read it, they are not compliant.

Goodwin’s new method: put “protective clothing” on the label

In order to make RFID tags work smoothly, Goodwin has launched several clever solutions:

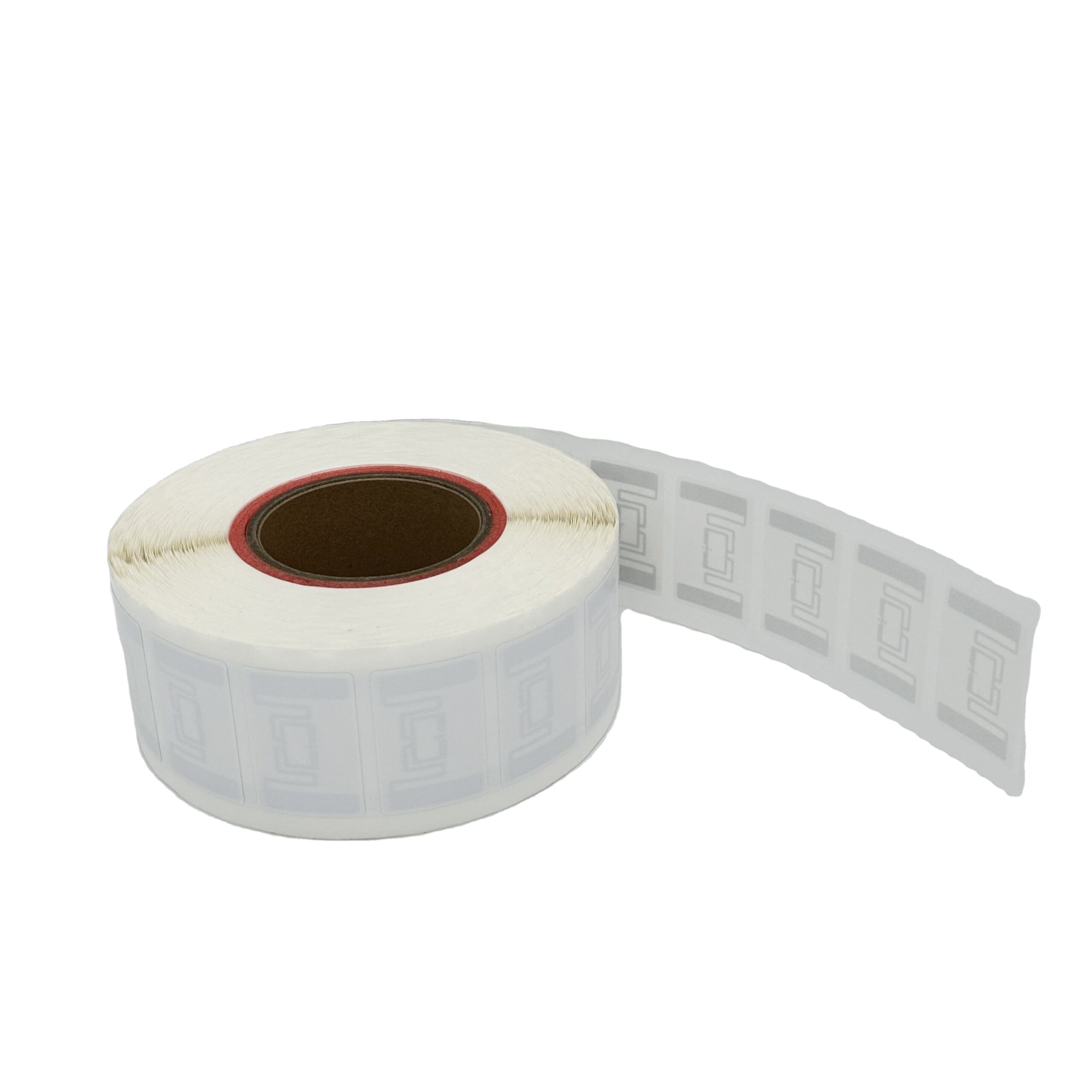

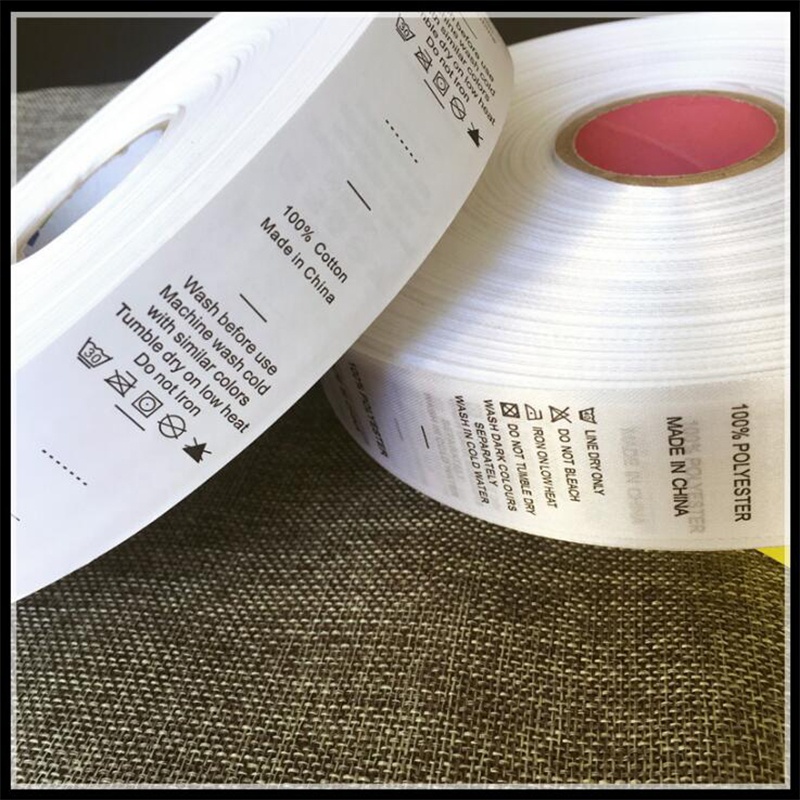

New label structure: They use a multi-layer design to “wrap” the RFID chip and antenna in a layer of special material to isolate the interference of liquids and firmly stick to the bottle without falling off.

Stick it on the top of the bottle mouth: The label is not attached near the liquid, but on the top of the bottle or hung on the outside of the bottle, so that the signal is clearer.

Intelligent bottling: Use precise filling equipment to ensure that there is no liquid interference around the label.

These tags use 13.56MHz high-frequency RFID technology, and the chip type can be selected from F08, MIFARE 1K, Ultralight C, Ntag213, 215 or 216, with storage capacity ranging from 144 bytes to 1KB. The label material is made of durable PET, with a reading distance of 1 to 5 cm, can be erased and written 100,000 times, and supports customization.

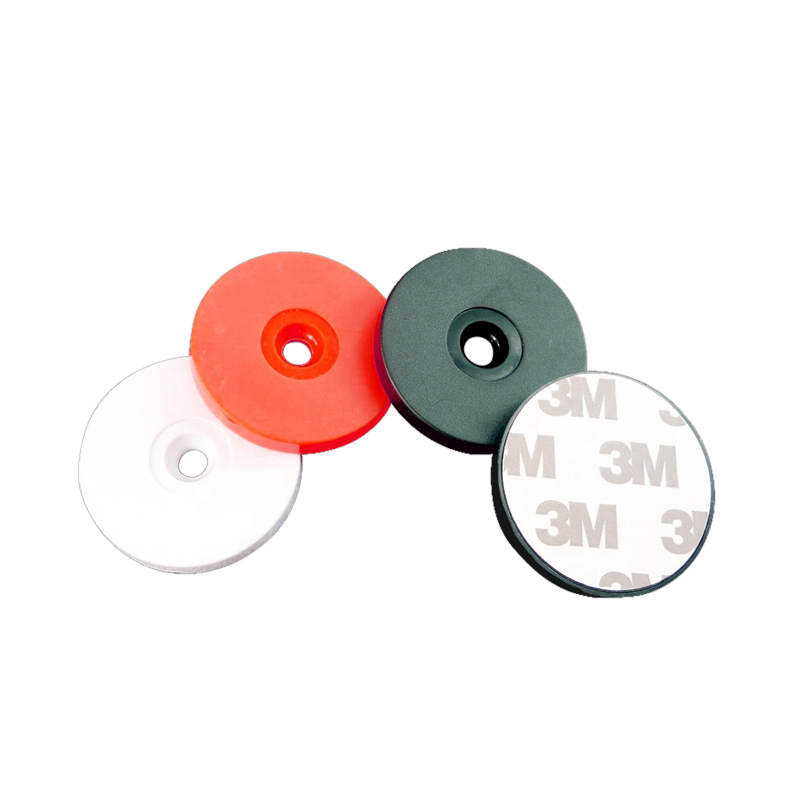

A better idea: “hide” the label in the bottle cap

In addition to improving the way the label is attached, Goodwin is also testing a more advanced method – putting the RFID chip directly into the bottle cap. This way the label is away from the liquid and there is less signal interference. This technology is being tested in the RFID laboratory of Auburn University and may become a new industry standard in the future.

Liquid products can also be “seen”

Goodwin Inc.’s efforts not only solve the technical difficulties of RFID in liquid commodities, but also help the entire industry take a big step towards intelligence. As more and more businesses use RFID to manage inventory, in the future, every bottle of liquid product we buy may have a “smart electronic tag” behind it to help us manage goods faster and more accurately.