Nowadays, people all over the world are trying to use cleaner and more environmentally friendly energy, and solar energy is one of the most popular ones. In order to make solar panels faster and better, we need to use some “smart” technologies, such as RFID.

What is RFID and what can it do?

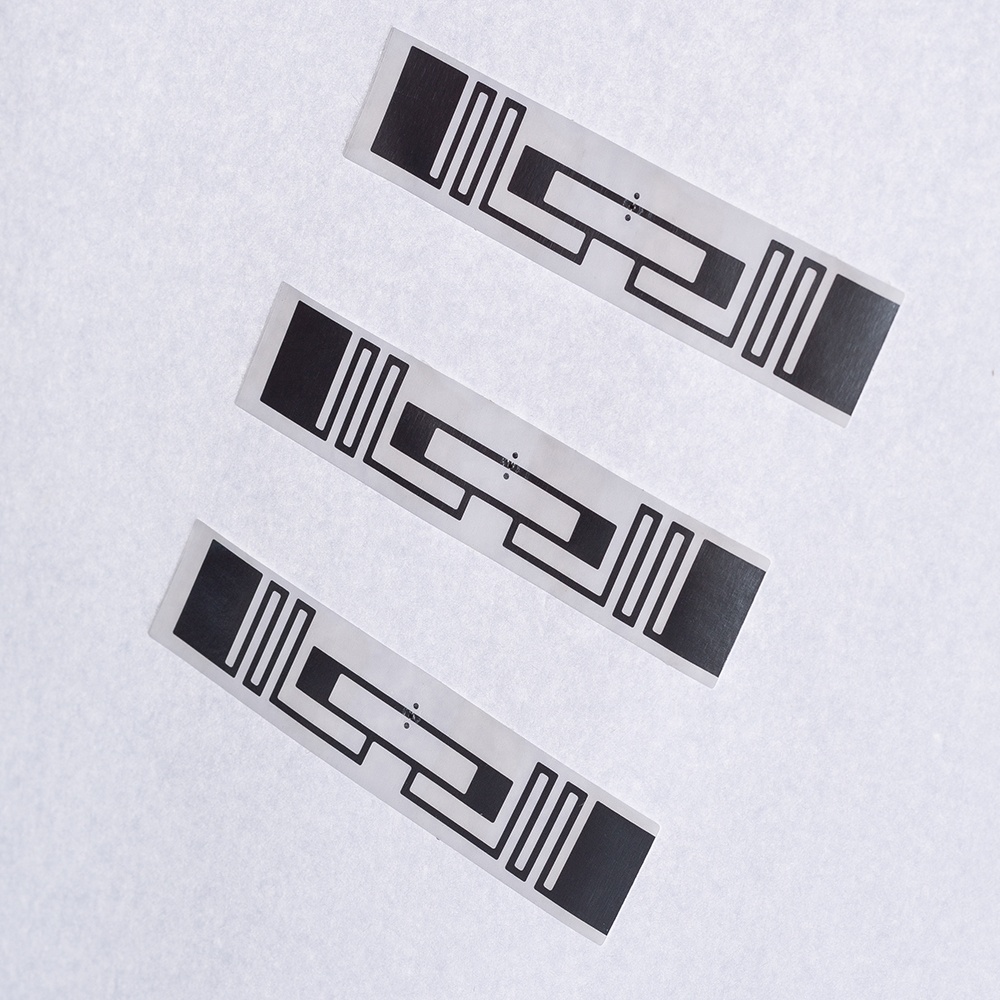

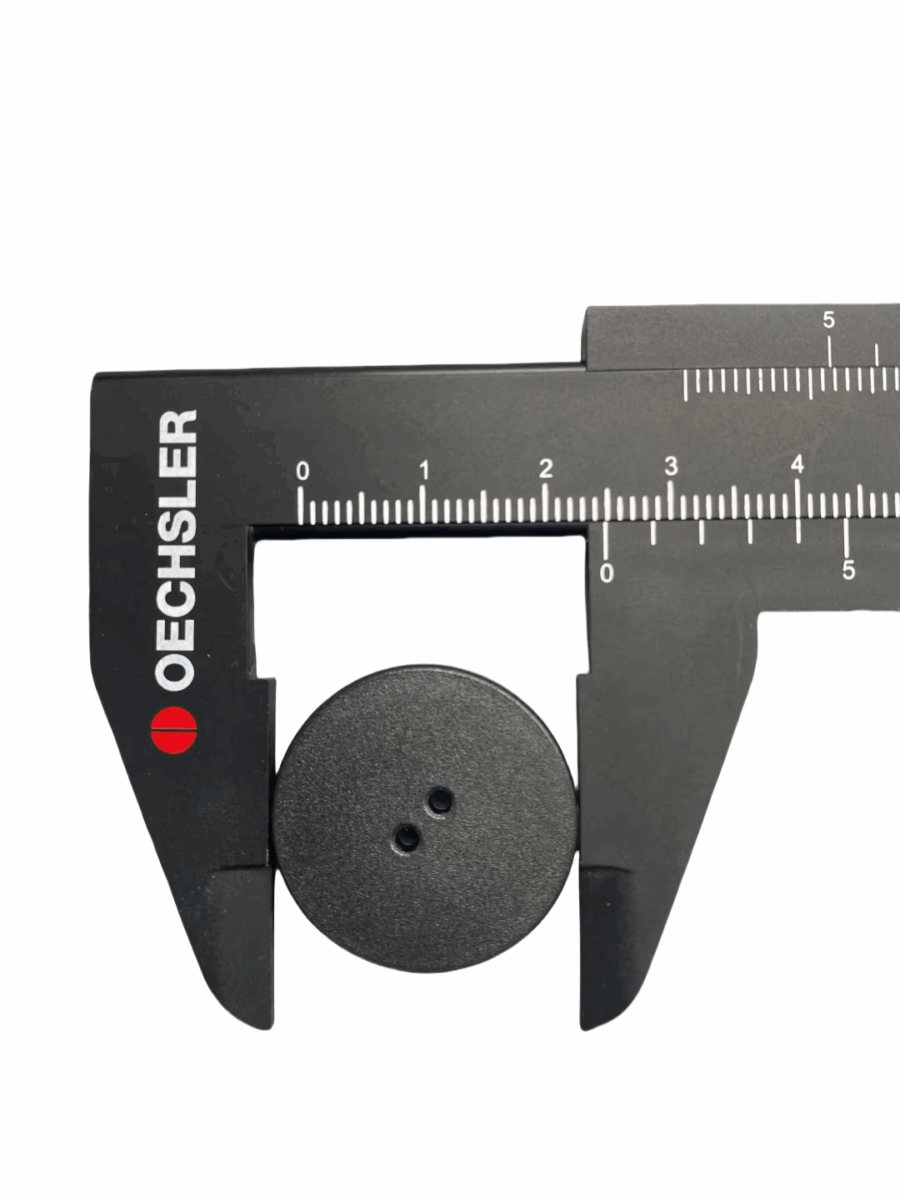

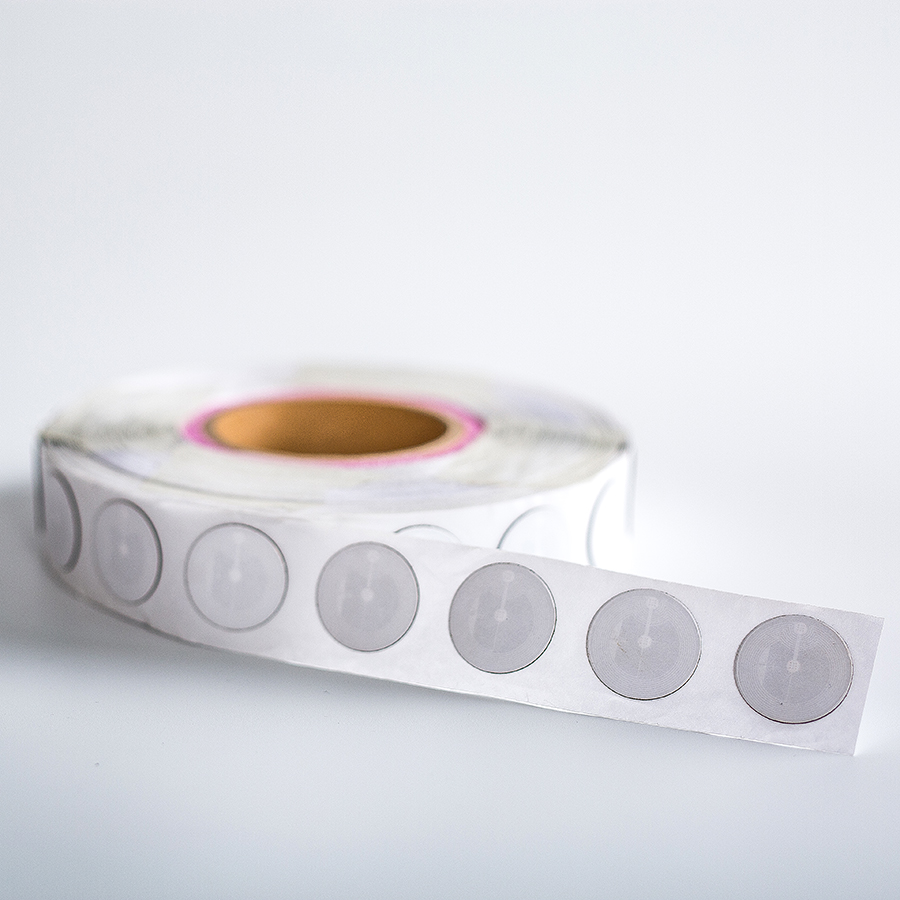

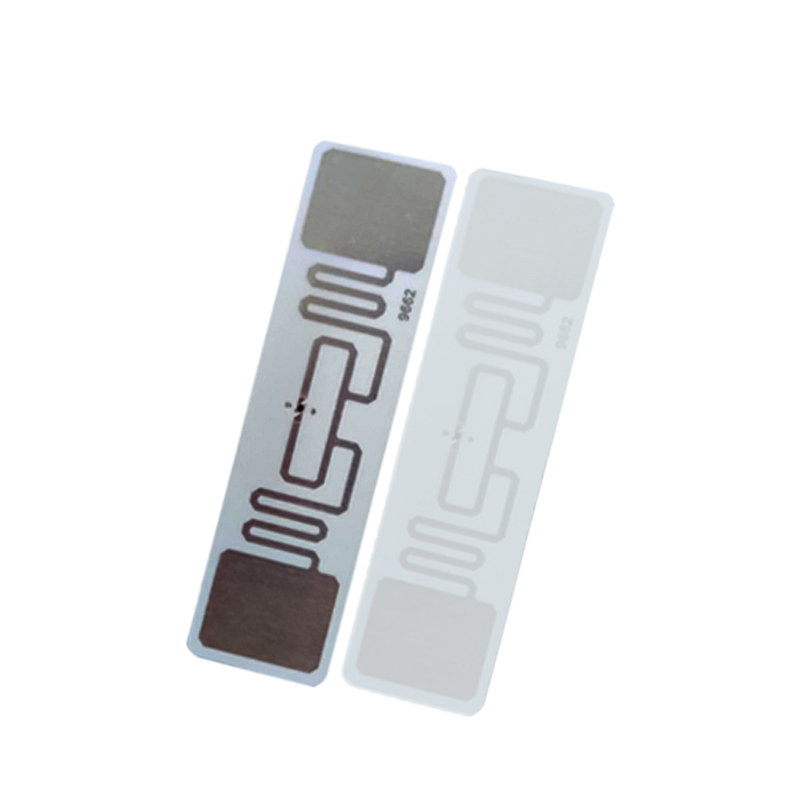

RFID is like a “wireless ID card” that can write information on a small tag. These tags are attached to objects, and when they are scanned by a machine, you can know who it is, where it comes from, and where it is now.

This technology is particularly useful in the production process of solar panels. Let’s take a look at how RFID helps:

1. Make the production line run faster

In traditional factories, many things have to be done by people, such as scanning barcodes with scanners to record the progress of each solar panel. This is not only slow, but also prone to errors.

Now, if you put RFID tags on silicon wafers or components, it’s like installing “little black boxes” on them. The production time, process parameters, batch number, etc. of each panel can be automatically recorded and tracked without manual operation. This not only saves time and effort, but also greatly reduces the chance of errors.

2. Make quality control “transparent”

The quality of solar panels is very important. If there is a “problem panel”, the entire system may be affected.

With RFID, every step of each panel, from raw materials to final testing and packaging, can be recorded. If there is a problem, just scan the RFID to know which batch and which process link has gone wrong, which is convenient for quick traceability and repair.

What’s more, the factory can also use this data to make “predictions” and find out in advance which materials or processes are prone to problems, so as to make improvements in advance.

3. Warehouses become smarter

Solar panels are large and heavy. They are moved in and out of the warehouse by people, which is inefficient and easy to move wrong.

After installing RFID tags, the forklift in the warehouse can automatically “scan” while driving to know which panel is being moved and where to send it. The inventory system will also be automatically updated without manual recording.

4. “Equip solar energy with a brain”

The future solar energy system will not only generate electricity, but also “speak for itself”.

For example, some companies combine RFID with the IoT platform to remotely check the working status of solar panels. If the power generation efficiency of a panel decreases, the system will automatically remind the maintenance personnel.

If it is a rental company, you can also know where the solar equipment is now and whether it is used correctly, which greatly improves management efficiency.

Summary: RFID makes solar factories smarter

In the past, RFID was just an “auxiliary tool”, but now it has become an important role in promoting the progress of the entire solar industry. It can help us produce faster, better control quality, manage warehouses more intelligently, and make solar systems as smart as “having brains”.