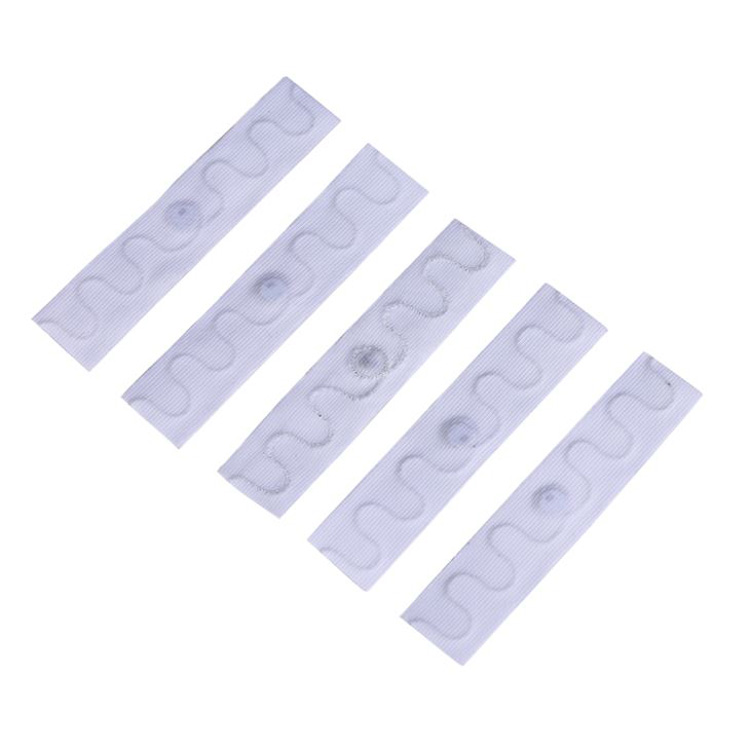

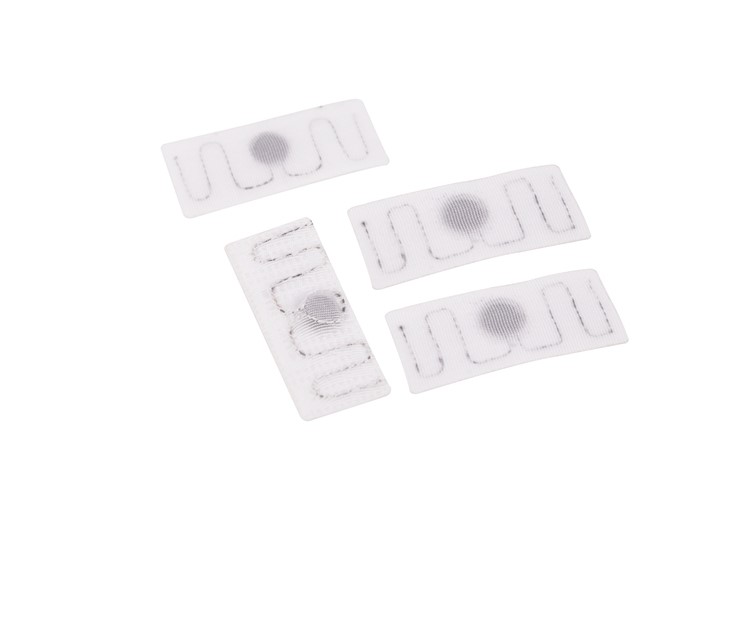

Washing Resistance soft Textile UHF RFID Laundry Label

UHF Woven RFID Laundry Label

860-960mhz ISO 18000-6C UHF 860-960Mhz textile UHF Woven RFID Laundry Label

Technical Specification:

| Product Name | UHF RFID Laundry Label Tag |

| Material | 50/50 polycotton |

| Size | 35mm x 15mm; 58mm x 15mm; 70mm x 10mm; 70 x 15 mm; 75 x 12mm; 75 x 15 mm or customized Thickness 1.6 mm |

| Weight | 0.3g |

| Oprating frequency | 865~868MHz,902~928MHz |

| Memory | 96 bits EPC |

| Chip | U8, U9, M730, MR6, M750 etc for option) |

| Reading distance | Up to 5m(Foxed reader) Up to 2.5m(Handheld reader) |

| Mounting method | Sewing, Heat-sealing, Pouch |

| Affixes to | Linens and garments |

| Warranty | First of 200 wash cycles or 100 autoclave cycles or 3 years from ship date |

| Typical washing cycle | Washing: +90°C (I94°F), I5 minutes |

| Drying: +I80°C (356°F), 3 minutes | |

| lroner: +200°C (392°F), I2 seconds | |

| Water Extractor: 60 bar, 80 seconds | |

| Autoclave | Air removal: +I00°C (+2I2°F), 5 minutes, 0.I bar |

| Sterilizing: +I34°C (+273°F), I0 minutes, 3.25 bar | |

| Sterilizing: +I34°C (+273°F), I0 minutes, 3.25 bar | |

| Patching instructions | +204°C’ (399°F), 12 seconds, 0.5 kg/cm2 |

| Storage Temperature | -40°C’ to +I20°C (-40°F to +248°F)

|

Frequently Asked Questions (FAQ) – Textile RFID Laundry Label

1. How does the Textile RFID Laundry Tag improve inventory management?

The Textile RFID Laundry Tag provides precise tracking of garments, automating the process of inventory management. By using UCODE® 9 chips, businesses can instantly monitor the location and status of each garment, improving operational efficiency and reducing manual errors.

2. How durable are the Textile RFID Laundry Tags?

Our washable RFID tags are designed to withstand up to 200 wash cycles, and in some cases, over 300. This durability ensures the tags remain functional throughout the garment’s life, reducing replacement costs.

3. What is the advantage of UHF long-range RFID technology?

With UHF long-range RFID tags, garments can be tracked over greater distances, speeding up processing times in high-volume environments like industrial laundries. This technology enhances automation, improving service levels and operational productivity.

4. How does RFID tagging address common laundry industry pain points?

RFID tags reduce manual tracking errors, ensure accurate asset management, and enhance garment durability. By automating tracking, businesses can save time, reduce losses, and increase profitability.

5. Why choose your RFID tags over others?

As a Top 5 RFID tag manufacturer with over 15 years of experience, we offer high-quality, durable solutions tailored for large-scale garment management, ensuring cost-effective and efficient operations.