Revolutionizing the safety and efficiency of heavy lifting operations

When it comes to moving huge rocks, steel or trees, safety is of the utmost importance. To make heavy work safer and smarter, Magni, the world’s leading telehandler manufacturer, has come up with a super-powerful new invention: a telehandler that is a crane, hoist and smart identification system in one!

This machine is not only powerful, but also a little “smart”. It can recognize what tools are installed and know how to move things safely, greatly reducing the chance of errors.

Why Magni uses RFID tags in its machines?

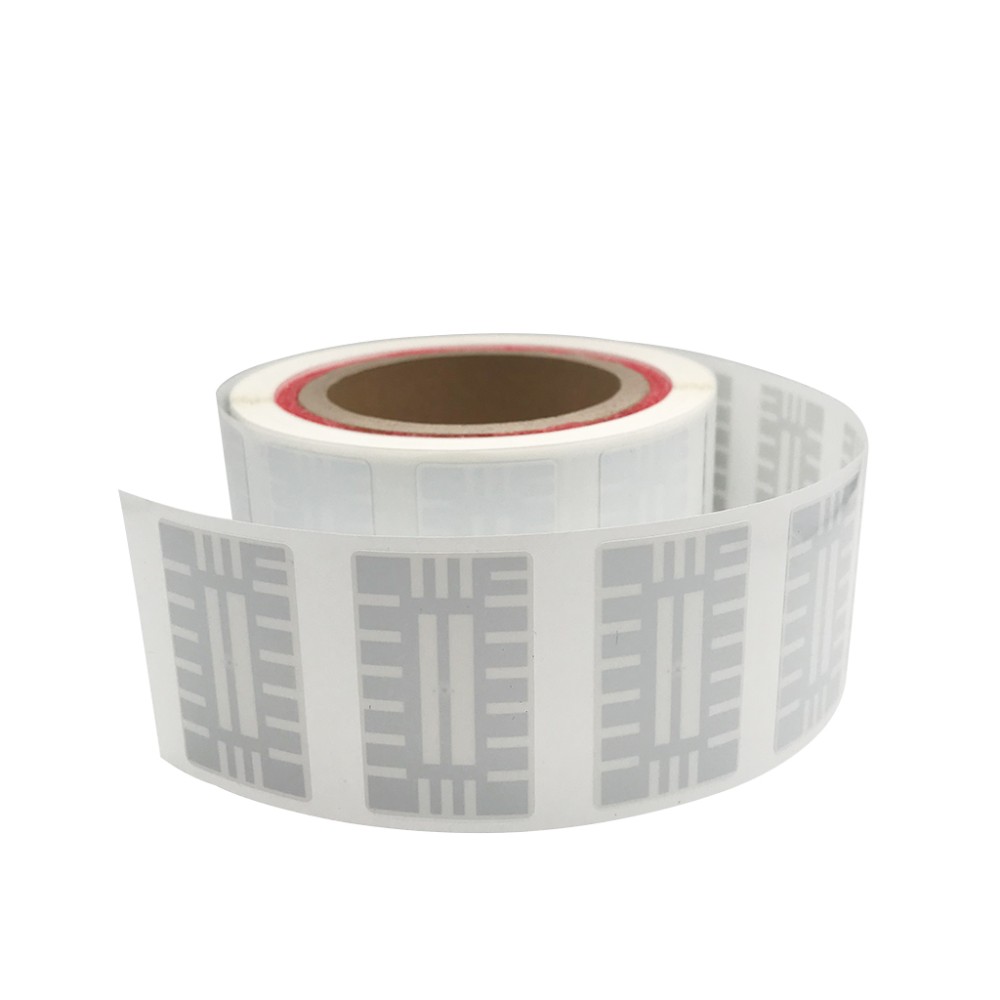

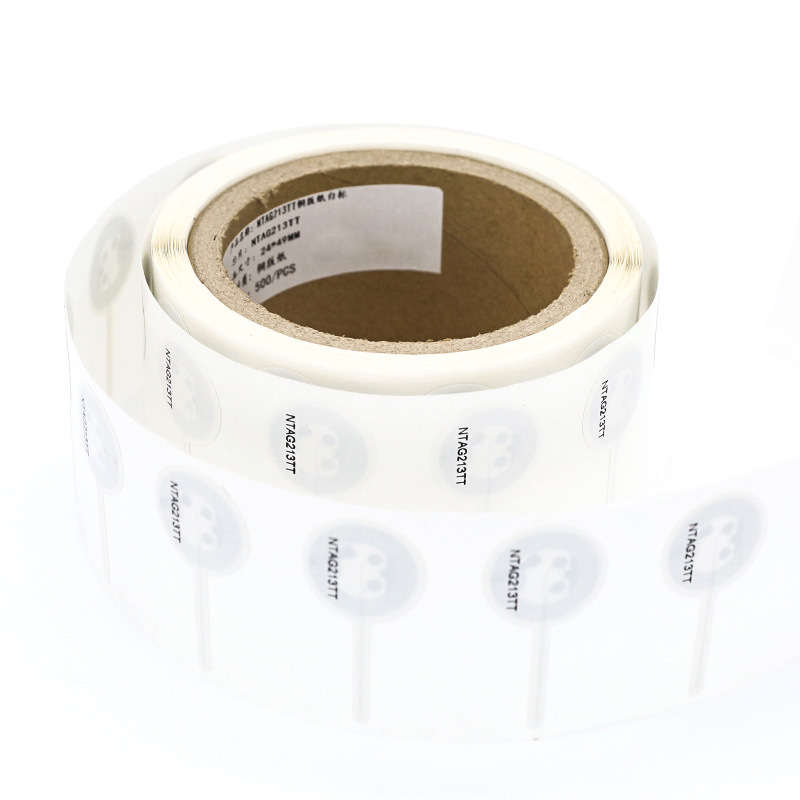

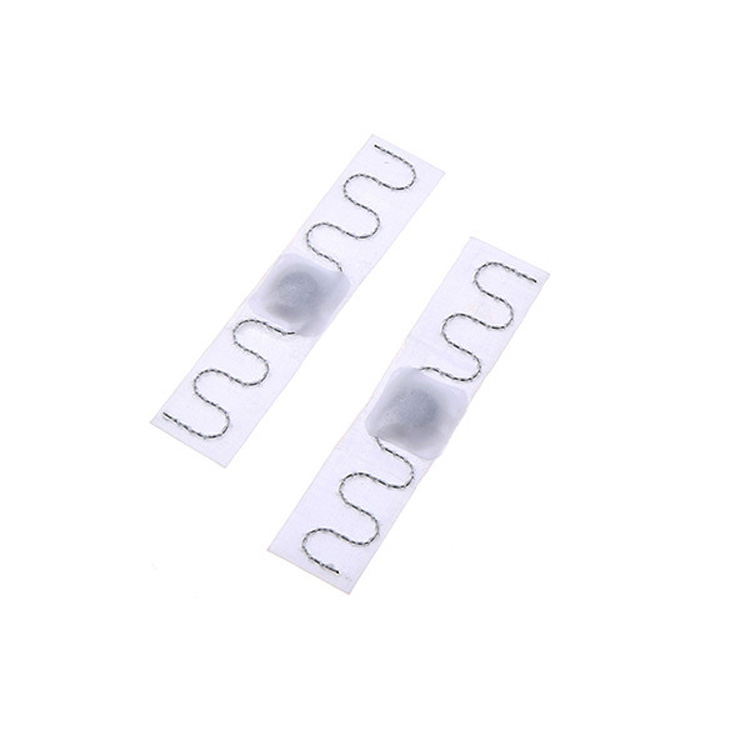

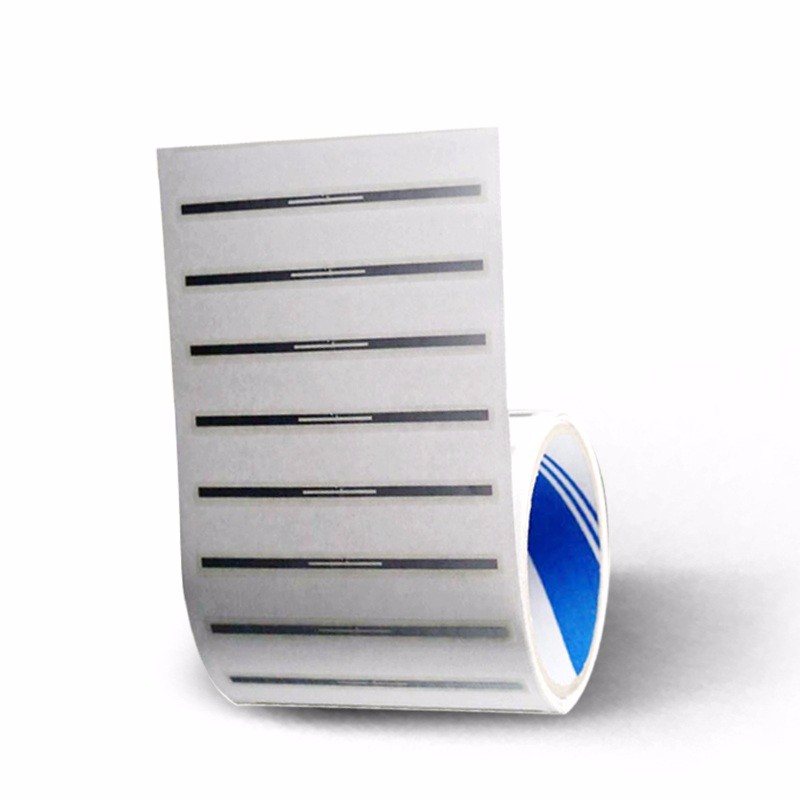

Imagine a machine lifting a steel beam weighing several tons. If the operation is wrong, it can be dangerous. Magni attaches a small RFID tag to each tool. This tag can be quickly “recognized” by the machine’s reader, just as easily as swiping a subway card!

Once the machine knows what tools it has installed, it will automatically adjust the length, height and angle of the boom, and can also give the safest operation suggestions based on the weight of the tool. Behind this, there are also weight sensors monitoring in real time to prevent the machine from tipping over due to overweight and ensure everyone’s safety.

With such intelligent guidance, even novice operators can work with peace of mind and minimize the chance of error.

Use intelligent management to improve work efficiency

In addition to safety, Magni also wants to make work faster and smoother. The machine has a large touch screen that can display clear site maps, camera images, and important data such as weight, height, and angle. The operator can see at a glance and make the right judgment quickly.

In addition, Magni is also equipped with an intelligent management system called Combi Touch, which can display various data in real time to help workers decide what to do faster, making every operation fast and accurate.

Technical parameters at a glance:

Chip type: Alien H9, Ucode8/9 (customizable)

Frequency: 860-960MHz

Protocol: ISO/IEC 18000-6C

Size: 100×33mm (customizable)

Memory size: varies according to the chip

Material: coated paper, PVC, PET (customizable)

Special features: waterproof, weatherproof

Communication method: RFID, UHF